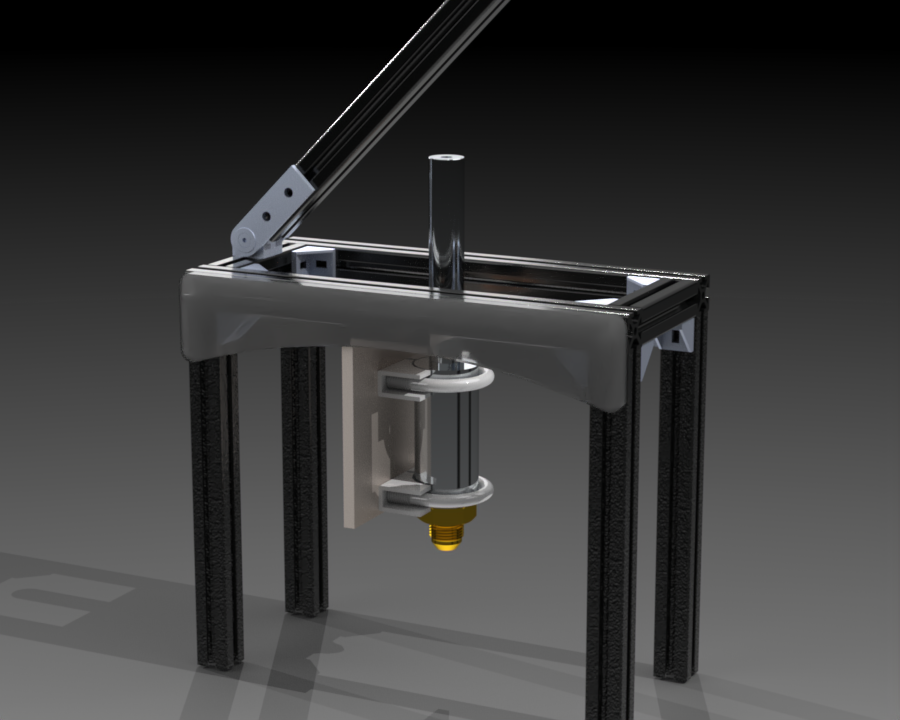

It’s been a long weekend, and while trying to relax I’ve been thinking about the next steps in this process. During testing, the most apparent issue was the rigidity of the molder’s stand. As you can see in my previous posts, the stand was made of poorly cut 1″x1″ lumber mended together with steel brackets. The barrel was also attached with steel brackets. You can probably guess that this was not in any way stable enough to test the barrel properly.

So, I’ve finally made what I should have made weeks ago: an aluminum extrusion test stand. I actually think that this framing method might be similar to the final product’s. Aluminum extrusion is strong, versatile, and cheap which makes it perfect for this project. I was able to use my new miter saw along with the appropriate blade to cut the aluminum exactly to length and fastened it with special corner brackets. The new stand is very stable and allows for future design changes or additions to the frame.

The next step is to mount the barrel in a more secure way than using steel brackets. I have a good idea for how to do this inexpensively and I will be updating you on that in the future. I also need to start working on making an actual mold to test this with as I can’t use random sockets I find laying around much more. If you have ideas for what to inject first, please let me know! I’m hoping to start building a community around this project, and I would like to send anyone interested in following the first few shots from the prototype machine!